Sustainable Building Construction And Environment Protection

INTRODUCTION

Today it has become a common word/fashion to be ‘green’ without knowing any details about it. Many persons assume that such green measures would increase the cost of Building manifold. It is, therefore necessary to demystify this by clarifying the related issues. Essentially, this is possible by affecting a series of small term measures which are very doable and also do not cost much more than conventional methods. The entire exercise should lead to more holistic green design which in the end is more satisfying. Although there is an inherent resistance to trying out something new compared to tried and tested methods, innovation is certainly required if one hopes to make a substantial impact on the development scenario.

Building Industry is producing second largest amount of Green House Gases (almost 35%) and Waste (Demolition Waste). Thus, buildings have major environmental impacts over the entire life cycle of human beings. Resources such as ground cover, forests, water and energy are being depleted to construct and operate buildings. In reference to green building concepts some basic parameters associated with green building concept are defined and discussed here.

Sustainability:

Sustainability of System is a primary issue which will affect the entire Eco System on Earth and influence the Environment along with availability of total resources on earth. The sustainability concerns the environment and securing health for citizens is an essential requirement which should aim for availability of resources and reducing, re-using or recycling (3R’s) of wastes through their safe, efficient and scientific management. Factors affecting existence of human mankind on earth and factors in sustainable development are:

- Population growth and its Urbanization

- Extensive use of Conventional Energy

- Excessive Waste Generation

- Global Warming

- Limited supply of Natural Resources

- Pollution of air, water and soil.

Thus, sustainability of system is defined as meeting the needs of the present without compromising the ability of further generations to meet their demands. Visualization of sustainability is the realization that today’s population is merely borrowing resources and environmental conditions from future generations. Some of the above factors are discussed in brief here.

Global Warming:

In 2004, the average worldwide power consumption of the human race was about 15 TW or 15×1012 W with 85% coming from burning fossil fuels like Oil, coal, natural gas etc. The energy consumption in India increased many fold, say from 4.16 to 16.8 Quadrillion Btu in the last few years, putting India next to US, Germany, Japan, and China in total energy consumption. Because of such thermal power generation and various other human activities, lots of Green House Gases (GHG) is produced. Following are some of the main components of Green House Gases, which enter into atmosphere.

- Carbon Dioxide (CO2)

- Methane (CH4)

- Nitrous Oxide (N2O)

- Fluorinated Gases etc.

In addition to the above gases, Volatile organic compounds, asbestos, carbon monoxide, nitrogen dioxide (NO2), Sulfur Dioxide (SO2) and combustion gases also affect air quality. These are introduced in the indoor environment also by paints, glues, solvents, wood preservatives, installation of carpets or through cleaning products.

Effect of Global Warming:

Because of climate change, the air is getting warmer – summer comes sooner in most Continents including Europe and America. Sea level is rising – the Maldives Island is sinking. Mangrove forests of SUNDERBAN in India, which are the unique islands and world’s most prosperous group of 104 Rainforest Islands, are likely to be wiped out from earth’s map soon. In fact 16% of Sunderban Islands have already been submerged in the ocean. Now the threat of submerging is looming large on Sagardeep, the 4th biggest of the existing island. It is also on this Island, that the annual Mela of Gangasagar is held and visited by Millions of pilgrims.

Thus, the global warming may result in:

- Likely temperature rise between 1.80C to 40 C

- Sea level rise – most likely to be 0.28 – 0.43 m

- Artic summer sea ice disappearing in this century.

- An increase in heat waves likely

- A likely rise in tropical storm intensity.

- Erratic or Changed Weather conditions.

According to NASA satellite data, the Arctic Ocean could be nearly ice free very soon, much faster than previous predictions. Faster melting of ice there means eventual sea level rise and more immediate changes in winter weather because of less sea ice. While sea ice reflects about 80% of the sun’s heat off earth. When there is no sea ice, about 80% of the heat goes directly into the ocean which than warms up everything else. Warmer oceans ultimately lead to more ice melting.

The glaciers feeding water for the Holy River GANGA are also melting faster than it should. It means the River GANGA could become a stream in another 60 years or so. This would leave more than 60 million people hungry and thirsty who are living and surviving on the banks of this river all along its alignment / route.

Population Growth And Urbanization:

In 1950, New York and few others were the only cities in the world with a population of more than 10 million. The number of cities with a population of more than 10 million increased to 5 in 1975 and 17 in 2001. It is expected that this will increase to 25 or more cities by the year 2015. Currently, about half of the world’s population lives in urban areas. By 2030, urban dwellers will make up roughly 60% of worlds population. The percentage of urban population in India was about 27.8% in 2001. It is projected that in Asia and Africa there will be more urban dwellers than any other continent of the World and Asia will comprise 54% of world’s urban population by 2030. In India the urban population may increase to 38% or so by 2011. Thus, a News Item: New Delhi, April 23 –

By 2030, Indian towns may turn dry, stinking hellholes, Dry taps, untreated sewage and piles of solid waste strewn all around.

The report McKinsey & Company predicts, that Such phenomenon may become a stark reality of our urban landscape by 2030, when India’s urban population will grow from 340 million in 2008 to 590 million i.e. about 40 per cent of the total population which will be twice the present population of the United States. Fifteen or so cities will have a population of more than five million by 2030 with five states – Tamil Nadu, Gujarat, Maharashtra, Karnataka and Punjab – likely to be more than 50% urbanised. Also, 70% of India’s GDP will come from cities – up from 58% – and drive a near fourfold increase in per capita income. The problem is much bigger, as only 38 percent of the population, 286 million people, in these cities has access to sanitation facilities and 78 percent to clean drinking water.

“India’s approach to urbanisation is likely to result in urban gridlock and chaos, jeopardising the 7.4% growth rate. India needs to act with urgency for well being of its citizens and economy,” says Ireena Vittal, partner, McKinsey & Company.

Population growth coupled with urbanization results in significant impacts on the environment and many other related problems like:

- Increased Ambient Temperature

- Decreased Air Quality

- Increased Water Run off and Decreased water Quality & quantity.

- Changed Weather Patterns

- Loss of Aesthetic Beauty/Character of the Community places.

- Reduction in Farm Lands and Subsequent Food Shortage.

- Deforestation.

Deforestation is closely linked with negative environmental consequences such as loss of bio diversity, Global warming, Soil erosion and desertification. This also lowers water tables and flood volume increase. Deforestation also affects rain forests.

Waste Generation:

Huge amount of solid waste is generated every day in each Indian city. For example Delhi alone generates about 650 tons of Garbage every day. By 2020 its amount may reach 1,800 tons. In the cities, the disposal areas are outside city which are miles apart and require land and fuel for disposal. Such amount of waste disposal is a Herculean task and needs space for dumping and fuel for transportation upto disposal areas. The central pollution Control Board estimates the current quantum of municipal solid waste generation in India to the tune of 50 million tons per annum. Per capita waste generation in major Indian cities range from 0.4 to 0.8 Kg per day per person. A typical waste dump is shown in figure 1. In addition, the hazardous waste generation is around 4.4 million tones. Construction industry also produces huge waste called demolition waste or MALWA. Out of total waste generation, construction industry accounts for about 15 million tons. As far as possible, this should be managed locally or recycled and used in construction industry itself.

Figure 1 – Atypical Waste Dump on the sides of Road.

Figure 1 – Atypical Waste Dump on the sides of Road.

About 380 million tonne of solid waste per annum may be generated by 2030. Out of this, only about 2/3rd may be collected because of inadequate facilities. Emerging cities generate 68 percent of the total waste, but don’t have treating facility.

Similarly nearly 90 per cent of the liquid sewage- 38,254 million litres -generated daily by cities that flow into streams, rivers and sea doesn’t met environment norms. Waste water should be of bathing quality to meet the standard of waste water disposal being generated by cities. In cities, where 36 percent of the country’s people live, is polluting over 70 percent of the water sources, says a report released by the Central Pollution control Board. Further, 70-80 per cent of the sewage generated in the country would go untreated. The report states that if existing services are not improved drastically, the per capita water supply to an average citizen could drop from an average of 105 litres to only 65 litres or less a day in the next few years. India’s current per capita spending on urban infrastructure of Rs. 784.00 ($17) is just 14 per cent that of China’s Rs. 6,030.00 ($116).

Waste Management:

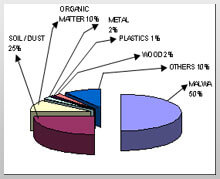

The Waste usually relates to materials produced by human activity and waste management is generally undertaken to dispose and reduce their effect on health and aesthetics or amenities. The waste management is also carried out to reduce the effect on the environment and to recover useful material or resources from it. Waste Management is generally Collection, transport, processing, recycling or disposal of waste materials. Waste management can involve solid, liquid or gaseous substances to recover or dispose them. A typical waste product distribution in any solid waste dump is shown in figure 2. Waste management will involve different methods for its processing as given below:

- Disposal for landfill and incineration

- Recycling – physical and biological processing

- Energy recovery

- Methods of avoidance and reduction of waste.

Figure 2 – A Typical Analysis of Waste Dump on the Road Side

Most people don’t realize that solid waste reduction and/or its recycling will help address global climate change. The waste contributes to greenhouse gas emissions and thus Waste prevention and/or its recycling will reduce greenhouse gases and methane gas emissions etc. Creative ways have been found to reduce and better manage Municipal Solid Waste (MSW). This includes source reduction, recycling (including composting), and disposal. The most environmentally sound management of MSW is achieved when these approaches are put into practice. In future every country has to accord importance to waste management in order to have sustainability. Out of these, recycling is most relevant as it will also save on the resources. A typical method or steps for this are given below.

Recycling the Waste:

Step 1: Collection: Recyclables differ from region to region, however there are four primary methods:

1) Curbside,

2) Drop-off centers,

3) buy-back centers

4) deposit/refund programs

5) Municipal Collectors.

Step 2: Processing: Irrespective of the method used, the next stage of a recyclables journey is the same. They are sent to a recovery facility to be sorted and prepared into marketable commodities for manufacturing/Processing.

Step 3: Manufacturing: Once separated and cleaned, the recyclables are ready to undergo the third phase of recycling loop. Many of new-gen products are being manufactured with total or partial recycled content. Some household items that contain recycled materials include newspapers, paper towels, soft drink containers, steel cans and plastic laundry detergent bottles. Recycled materials are also used in applications, such as recovered glass in roadway asphalt (glassphalt) or recovered plastic in road carpeting, making park benches, and pedestrian bridges. Demolition waste can be used in making fresh concrete or Highway Construction.

Step 4: Purchasing Recycled Finished Products: The cost of such items may be slightly less or equal to new parallel items, but public as well as government should encourage them to be purchased at priority. Purchasing recycled products completes the recycling loop. By buying recycled items, governments as well as business men and individual consumers, each play an important role in making the recycling process a success. As consumers continue to demand sustainable products, manufacturers will meet these demands. Since the waste is being generated all over the country, so as far as possible, its management efforts should be focused at decentralized locations through small scale units. This will also greatly help in employment generation for local youth and women. Few such examples of recyclable process are given here.

A) Manufacturing the Building Blocks/Bricks out of Demolition Waste:

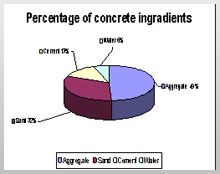

The Building Demolition waste (MALWA) can be easily used in Construction industry itself. This can be converted to Course aggregate and have appropriate use to make concrete blocks / bricks and in low grade concrete. Generally the requirement of aggregate in a concrete is about 50% as shown in figure 3. Thus recovering the course aggregate from Demolition waste after light crushing and sieving and then mix nominal amount of cement say 150 Kg per cum of concrete and other ingredients can be casted in the form of conventional type of bricks. Typical shapes of such bricks are shown in figure 4. After sieving, fines left can be used as filler in plinth or highway embankment or can go back to river bed from where river sand is coming.

Figure 3 – Ingredients required in a typical Concrete Mix

Figure 4 – Typical Solid or Hollow Concrete Blocks made with demolition waste aggregate

Figure 4 – Typical Solid or Hollow Concrete Blocks made with demolition waste aggregate

Advantages of Using Waste Concrete Bricks/Blocks:

- By making use of locally available demolition waste aggregates, there would be sufficient reduction in aggregate requirement at construction site.

- It would help in improving the local economy rather than spending for procuring burnt bricks from distant places

- CO2 emission is almost nil in this process.

- Top soil of earth will be saved which is used in making burnt clay bricks and thus environmentally viable.

B) Utilization Of Polythene Beg Waste In Construction Of Bituminous Roads

Polythene Beg Waste Scenario:

Polythene beg waste has become a nuisance in each city, village or even on roads and any where & every where. Once polythene begs are used, they are generally thrown out. The consumption of polythene beg has increased from 4000 tons/annum in 1990 to 4 million tons/annum in 2001 and it is expected to rise to 8 million tons/annum during the current year 2010. Generally polythene begs are not reused; however, some of it can be reprocessed by converting it to granular form and than re – rolling it as sheets. This material is non degradable and do not undergo bio-decomposition. Hence, they are either land filled or incinerated. Both are not eco-friendly processes and they pollute the land and water bodies.

Figure 5 – A typical Garbage Dump with polythene begs

A typical garbage dump having mainly polythene beg waste is shown in figure 5. The distribution of waste items in it is similar to as shown in figure 2. Polythene begs waste or polythene begs is generally a form of Polymer and its properties are similar to Polymer to a great extent. In the investigations carried out by the author, common bitumen has been modified with waste polythene beg pieces and Bituminous mix / concrete is made. This is tried as top layer or bearing coat of flexible pavement. Polythene beg mixed Bituminous mix showed better binding property, density, stability and it is more resistant to water exposure.

Preparation of Bitumen Blend:

Waste Polyethylene carry bags were collected from waste dump. They were cut into pieces using shredding machine in the pieces of 2- 5 mm size as shown in figure 6. The Bitumen was heated up to a temperature of about 140-1500C, then polythene beg pieces were slowly added to the hot bitumen as shown in figure 7. The mixture was stirred well using mechanical stirrer for about 5-10 minutes in hot condition.

Figure 6 – Waste Polythene beg in Shredded form

Properties of Polythene Waste modified Bitumen blend:

Properties of such waste modified bitumen were found and compared with normal Bitumen, PMB and CRMB to see the suitability of its use for road construction. The Mix of Bitumen with waste polythene beg pieces is used to determine the various properties like penetration, softening point, flash & fire point, ductility etc. It was found that these properties are quite similar to normal bitumen and suitable for bituminous road construction. Then its suitability as blend for road construction is investigated as given below.

Figure 7 – Process to add Shredded polythene beg waste in hot bitumen

a) Use of Modified Bitumen in Top layer of Pavement (SDBC):

The polythene begs mixed bitumen was tried for a SDBC mix. Generally this type of Bitumen mix is used in the top or bearing layer of Road pavement called SDBC or Bituminous Concrete. The polythene begs modified bitumen was used with the 10 mm down size aggregate and stone dust mixture in SDBC Mix. The utility of the polythene beg waste blended bitumen-aggregate mix for flexible pavement construction was characterized by also studying stripping value and Marshall Stability value of the mix for the blends having polythene beg waste contents varying from 0% to 2.5%. Several trials were made to develop Job mix formula. Finally Bitumen blended with 1.5 % waste polythene begs was chosen for such trial because this percentage gives better density of Bituminous Mix and also the Stability

b) Use of Polythene beg-Waste Coated Aggregate as Perforated Polymer Concrete:

The polythene begs waste can also be used for producing Perforated Polymer concrete. Such experiment was done in the laboratory. The 10-20 mm aggregate was heated to a temperature of around 1200 C. The shredded polythene beg-waste was added over the hot aggregate while doing constant mixing to give a uniform distribution of polythene begs waste as shown in figure 8. The polythene begs got softened and got coated over the aggregate.

Figure 8- Mixing of Polythene beg waste in Hot Aggregate

Binding property:

The molten polythene begs waste inhibits good binding property. The polythene beg waste got softened easily without any evolution of gas around 130-140 0C. The hot polythene beg waste coated aggregate was cast in the form of block and compacted, as seen in figure 9. Further the polymer coated aggregate was soaked in water for 48 hours. There was no stripping of bitumen. This shows that the coated polythene beg material sticks well with the surface of the aggregate.

The molten polythene begs waste inhibits good binding property. The polythene beg waste got softened easily without any evolution of gas around 130-140 0C. The hot polythene beg waste coated aggregate was cast in the form of block and compacted, as seen in figure 9. Further the polymer coated aggregate was soaked in water for 48 hours. There was no stripping of bitumen. This shows that the coated polythene beg material sticks well with the surface of the aggregate.

Figure 9 – Polythene waste coated perforated concrete block

Though, this is considered to be a pollution menace, it can find its use in these processes and thus can help solving the problem of pollution, because most of the polythene begs waste is polymers. Studies on the use of polythene beg-waste as a blended material with bitumen, suggest that the blends behave similar to PMB, thus having improved properties compared to plain bitumen.

Advantages of Using Polythene Beg Waste In Road Construction:

1. Disposal of Polythene beg Waste becomes easier.

2. It can keep the roads and streets clean by not dumping Polythene beg waste etc on the road side.

3. It can generate work for unemployed people like collecting all polythene beg waste by Rag pickers etc, and deposit it at Bitumen or Hot mix plants.

4. Generally these polythene begs are lying on road sides and Street cows eat the kitchen waste. Along with it they also consume polythene begs giving rise to various diseases in Stray animals.

5. It will save the resources like Bitumen / Polymers.

C) Composting or Utilization of Kitchen / Organic Waste as Manure:

The kitchen waste, farm waste and similar other organic wastes which are biodegradable can be used for composting to make farm manure. This can be done by Earthworm pits or NADEF technology, as is common.

Water Availability, Waste Water and Its Management:

In India, the water scarcity is much experienced due to the frequent occurrence of droughts and floods. Due to global warming, Himalayan glaciers are also shrinking. It may shrink from 500,000 sq km to half by 2030. Because of scarcity, many states wrangle over sharing of river waters. It is estimated that 80% of domestic needs in rural areas and 50% in urban areas are met by ground water. About 40% of water in large cities is lost due to leaky or causal attitude of citizens and bad management. In addition even the class I cities are treating only a small part of their effluents, while the smaller towns & Villages do not have any waste water treatment facilities. According to UN Report, one person in every six does not get safe drinking water and double those number lack adequate sanitation facilities. A typical waste water utilization system for a multistoried building is shown in figure 10.

- Waste water generated in cities, where 36 percent of the country’s population lives, pollutes over 70 percent of the water sources.

- India can treat only about 30 percent of the waste water generated every day. This means it can treat 11,500 million liter of waste water every day.

Agriculture requires huge water supply as it consumes over 80% of ground water. The water scarcity for agriculture is resulting in a host of crises such as food shortages, regional water conflicts, limited agriculture economic development and environmental degradation. Thus, a part of the treated waste water can be diverted for agriculture or in secondary use in buildings.

Figure 10- Waste water utilization system for a typical multistoried building

Construction Industry & Green House Gases (GHG):

Green and Sustainable Building Concept:

A green / sustainable building design is the one that achieves high performance over the full life cycle of building in one or more of the following areas.

- Minimizing the use of Natural Resource through efficient utilization of non-renewable natural resources like land, water and construction materials, including utilization of renewable energy resources. This may aim to ultimately achieve net minimum energy consumption.

- Minimizing emissions that negativity impacts our environment and atmosphere of our planet, especially those related to green house gases, indoor air quality, global warming, particularly Acid rain.

- Minimizing discharge of solid waste and liquid effluents including demolition and occupant waste, sewer and storm water and the associated infrastructure required to accommodate such removal.

- Better quality of indoor environment including air quality, thermal regime, illumination, acoustics/noise and visual aspects and provide comfortable human physiological and psychological perceptions.

Green Buildings adopt various strategies for water management like using low flow plumbing fixtures, electronic controls and fixtures, substitution of alternative water sources (Rain water, Reclaimed water and Gray water) for non potable purposes. Further use of rainwater harvesting, Zero – scraping and other technologies & approaches that result in reduction in the use of potable water can be used. There is depletion of resources, such as metals, fossil fuels and energy resources. Hence, it is of paramount importance to economically use or replace the use of these resources in construction with waste generated resources.

Sustainable Design and Life Cycle Management:

More than any other human endeavor; the built environment has direct and long lasting impact on biosphere. Nearly one-eighth of the global economy is devoted to construction and about one half of the world’s major resources are consumed by construction and related industries. It is estimated that in US, the building industry involves the extraction and movement of more than 6 billion tons of basic materials annually (this represents 8% of USA’s GDP and 40% of extracted Material). Similar amount of Construction material is used in India. Residential and commercial buildings together use one-third of all energy and about half of all electricity consumed in the country. They also account for 47% of Sulphur dioxide emissions, 22% of nitrogen oxide emissions and 10% of particulate emissions, all of which damage air quality. Further, buildings produce about 35% of the country’s carbon dioxide emissions- the chief pollutant blamed for climate change. Indoor air quality is inadequate in 30% of the buildings around the world. Construction waste is generated at the rate of about 0.5 tons per person each year in the US and about 0.2 tons per person each year in India. Of the approximately 145 Million tones of Construction and demolition waste generated in the US, about 90% is demolition waste. This waste has to be transported thus consuming more energy and creating pollution (transportation consumes about 40% of primary energy consumption). This condition is similar in India in big cities like Metros and municipal corporations which produce more than 65 million tons of waste every day. This pattern gives an indication that construction practices must be changed to effect the minimization of waste generation and its reprocess for utilization in construction itself.

Therefore, there is urgent need to develop effective approaches for life cycle design and management for the constructions of Buildings that will ensure sustainability in terms of material used & improved physical performance, cost effectiveness and environmental compatibility. Accordingly the following parameters may be looked into:

- Engineering Performance- Safety, Serviceability and Durability

- Economic performance: Minimum Life cycle and user Costs.

- Environmental performance: Minimum Green House Gas emissions, Reduced Material Consumption and better Energy efficiency etc.

Thus sustainability Design has to consider three major aspects i.e. Functional, Economical and Environmental. These all have inter dependence and will influence each other. To cover these three aspects, following are some of the Considerations for Sustainable Building Design and construction.

1. Use of resources should be at the speed at which they can naturally regenerate and discard only at the speed at which local ecosystem can absorb them.

2. Site planning should incorporate resources which are natural and locally available such as solar and wind energy, natural shading and drainage.

3. Resource efficient material should be used in the construction of Buildings and furnishings to lessen local and global impact.

4. The building should be designed for energy efficiency considering factors such as day lighting, passive ventilation, local climate etc.

5. Material and design strategies should produce good and healthy outdoor and indoor environmental quality.

6. Operation and maintenance system of buildings should support waste reduction and recycling.

7. System and Building Location should optimize employee commuting and customer transportation options.

Concrete: A Sustainable Construction Material:

Selecting construction Materials for high performance in Green Buildings is most difficult and challenging task for any design team. Several criteria’s are possible for this purpose and the best tool is Life Cycle Assessment (LCA). LCA provides information about the resources, availability, emissions and other impacts resulting from the life cycle of material used in buildings from extraction to disposal. The following simple guide lines/rules can be followed while selecting the material.

1. Actual material should consume least energy to Manufacture.

2. Material should involve least transportation distance – for the raw materials as well as for finished products.

3. Material used in it should not much influence the environment.

4. Product should be easy to recycle and safe to dispose

5. Product should be durable.

Among the various Construction materials, Concrete is the most versatile material for construction and hence it is the primary construction material in the World and cement is the main component of concrete. The use of concrete is increasing every day and is expected to double in the next fifteen years. As a rough estimate, two ton of concrete is used globally per person per year.

Concrete has many other positive qualities:

- It has high Strength and effective mass.

- It can be locally caste in shape.

- It can be used in main body or in interior and finishes – as required.

- Due to its use in interior, air quality does not get affected.

- It is easily cleanable

- It is almost impervious and resistant to insect damage

- It is fire resistance and is chemically inert for most chemicals.

- It is durable and Cost effective

- It can also be designed as pervious concrete and hence can be used as a paving material, allowing rain water to percolate through it into ground.

The recycling properties of concrete are also good. Crushed concrete waste can be effectively used as aggregate in roads, low grade concrete and in making concrete blocks similar to brunt clay bricks. Such concrete with waste aggregate can be easily used upto M30 grade. Recycling of concrete waste along with other construction waste will conserve resources and also save fresh construction material resources and land fill space? Further, use of manufactured sand and mining waste in place of river sand is also environment friendly and can be used in concrete. Several other byproducts like foundry sand broken glass, fly ash etc can be equally beneficial in concrete and will make it sustainable.

Typically concrete mix contains 12-15% cement and 75-80 % aggregates. Globally sand, gravel or crushed rock is used at the rate of 10- 11 billion tones every year and is effecting the environment and ecology. The cement can be partially replaced by cementitious materials or industrial by-products like fly ash; blast furnace slag, silica fumes etc in concrete mix. They can also be mixed in the cement itself, to save on the clinker. The Cement consumption in concrete can be optimized / minimized through any one of the following approaches:

1. Consume less Clinker in Cement making-up by adding Pozzolana- a waste material like fly ash or GGBFS in Cement.

2. Minimize Concrete consumption through innovative Architecture and Structural Design.

3. Use smart concrete mixture or i-crete as proportioning approach to save on cement in mix and better grading of combined aggregates & cohesive mix.

4. Consume optimum quantity of Cement in Concrete / Mortar mixtures by adding Pozzolanas in it.

Thus it will reduce emissions of CO2 and consumption of energy and raw materials. Replacement of such by-products can easily replace about 30-35 of cement volume. In addition, the service life of concrete structures can be improved by mixing cementitious materials in concrete as it will improve its impermeability.

Cement Production and Environment Impact:

The largest environmental impact of the construction industry comes from the cement manufacturing process that leads to relatively high greenhouse gas emission. This is one of the main factors responsible for climate change. It is estimated that modern cements contain on an average about 84% clinker and the clinker manufacturing process releases about CO2. Thus, each Kg of Cement Production generates about 850-900 gm of CO2 which goes in environment adding to Green House Gases (GHG). The Concrete Industry World wide consume more than 3.5 billon tons of cement per year and it would reach 4.5 billion tones by the year 2020. At present cement industry releases more than 3.0 billon tons of CO2 annually. In addition Cement production requires mining large quantities of raw materials such as lime stone, clay and coal resulting in deforestation and loss of top soil.

Sustainability and Infrastructure:

In the context of the construction industry, World has been facing several inter-related crises. These can be broadly classified in terms of:

- Environmental,

- Sustainability,

- Economy & Durability

The crises have risen from a number of factors such as technological advancements, industrialization, population growth, world-wide urbanization, and uncontrolled pollution and creation of waste. It is resulting in destruction of the world’s infrastructure, water shortages, environmental disasters, and material/structural deterioration by nature. Every crisis experienced in the world has a direct impact on the construction industry as the construction industry is closely interlinked with energy, resources and environment. Irredeemable environmental degradation can only be prevented by sustainable development of the industry, which can give better Quality of Life. Thus a Holistic approach to design and construction should be worked out by integrating all aspects from conceptual design to completion of project and maintenance during service life.

Life cycle is an important aspect of sustainability in concrete industry. When designing a building and minimize its environmental impact, it is important to look at the complete life cycle of the building including material acquisition, manufacturing, construction, operation, and reuse/recycling. This is called the “cradle to cradle perspective”. Reuse/recycling considers new options once the product or building has reached the end of its service life. Its successful integration with the virgin material in construction enhances the industry and also helps appreciate the material much beyond the value that it demonstrates.

Planning For Green Buildings:

It is a building which uses less energy and Natural Resources, creates less Waste & Green House Gases (GHG) and is healthier for people for living or working inside as compared to a standard Building. It is about creating buildings that optimize and match with the local ecology & use of local materials in construction and most importantly are built to optimize the use of power, water and Mineral resource. Normally for having green Building, one has to concentrate on following five items.

- Extensive use of Non Conventional Energy and Natural light.

- Minimum generation of Waste- all Solid, Liquid & Gases.

- Locally treat waste including waste water as resource and process it for reuse.

- Optimum use of Local & Natural Recourses for sustainability.

- Reduction on carbon gases /contents by better Planning and Design.

Figure 11 – A typical Green Building

The architects & planners should think about green concept in the planning of Buildings, integrating living & vegetation with architecture. This concept is fast gaining popularity around the world and a new term “Vegitecture” has been coined for it. With this the Architects and Planers should extensively plan to bring concrete jungles in Metro Cities to green jungles through “Vegitecture”. A typical Green Building is shown in figure 11 & green planning is shown in figure 12. Traditionally, buildings in India have been responsive to climate and local conditions resulting in a rich cultural heritage with respect to its regional context.

Conservation of resources revolve around three factors “3R’s” i.e. to Reduce, Reuse or Recycle, which are integral to traditional thinking in terms of energy saving and limited budgets available for construction. However, the present development scenario is quite different from earlier times due to diverse factors such as complex user needs, enhanced level of comfort and many technological advances. Yet it is possible to work within the constraints and find meaningful design solutions which can still use less energy & creates less waste during operation.

Figure 12 – A typical Green Planning campus

Some Benefits of a Green Building Concept:

Green building activities generally result in reduction of operating costs by 20-30% as compared to original conventional construction operating cost. However, construction cost of such Buildings may be 10-20% higher than conventional Building construction. Green buildings are designed to be healthier and having more enjoyable working environment. Some of the advantages of green building concept are:

- Significantly consistent/uniform lighting quality including more day light harvesting and use of shading, greater occupancy control and less glare.

- Reduced energy and water consumption without sacrificing the comfort levels.

- Improved thermal comfort and better ventilation.

- Limited waste generation due to recycling process.

- Improvement in workplace qualities can help reduce stress in workers and can result in better production. It is generally reported that productively of workers can be increased by about 10 – 20% while following such green house norms.

- Attracting and retaining good employees and developing better qualities in workers as they receive better physical, environmental and atmospheric benefits.

Energy Consumption in Buildings:

Energy in the form of Electricity, Coal, Petroleum Products, Wood etc are used extensively for each and every activity of mankind right from home living to office to factory production etc. Buildings are a major energy consuming sector in the whole system of energy supply. Building construction and its upkeep for livable conditions require huge energy in lighting, air-conditioning, heating, use of appliances etc. It is estimated that about 40 percent of total energy consumed, is used by buildings. Green Building concept i.e. energy efficient building is the one which can reduce energy consumption by about 40% as compared to conventional building by providing better light and air sources. Innovative design of building system can be devised so that the energy consumption could be as low as possible or around 80 – 100 Watts per square meter. To have energy conscious design features in Green Buildings following may be used:

- Alternative building materials such as composite walls to reduce heat gain and filler slabs to reduce the quantity of concrete in the structure.

- A central atrium to enhance cross ventilation and provide day lighting

- Solar PV lighting and pumps, rainfall harvesting and water conservation facilities incorporated

- Tinted glasses to reduce glare

- Passive downdraft evaporative cooling (PDEC) towers for providing comfort

Poverty Alleviation through Green & Waste Recycling Concept:

The technologies and the materials used for development should complement to the use of local and waste resources. If such technologies are developed, then the poverty alleviation in the developing countries can be effectively achieved by conservation of energy and reprocessing of Waste. The energy saved can be ploughed back for further development which creates a larger employment opportunity. The labor forces enhancing their capability and standard of living are used to avoid the widening of gap between haves and have not.

The technologies and the materials used for development should complement to the use of local and waste resources. If such technologies are developed, then the poverty alleviation in the developing countries can be effectively achieved by conservation of energy and reprocessing of Waste. The energy saved can be ploughed back for further development which creates a larger employment opportunity. The labor forces enhancing their capability and standard of living are used to avoid the widening of gap between haves and have not.

Processing of Waste can be taken up at a large scale and locally in each of 5,161 cities and towns of the Country as given in the example above. In processing of waste, huge manpower is needed to collect it, transport it, sort it, process it and market it in proper shape. We can produce hollow concrete bricks out of the processing of demolition waste (MALWA) and thus save energy and top soil of earth. This will not only generate jobs but will also save energy & resources of material which can be utilized at another place.

A typical view of poor people and unemployment in country is shown in figures 13 & 14. It shows how people are eager to collect a handful of waste concrete from a Highway Construction project. People line up when the concreting process in highway is going on where after edge cutting some concrete is removed and thrown as waste. To collect such waste fresh concrete poor people line up. Therefore, reprocess of waste will create employment opportunities. It can be a blessing for the fast developing country like India that the measures called for sustainable development can also be the measures of poverty alleviation. This will further the cause of sustainable development.

Figur e 13 & 14 – Poor people line up to collect a handful of green waste concrete

e 13 & 14 – Poor people line up to collect a handful of green waste concrete

Concept of Intelligent Buildings For Sustainable Development:

An intelligent or smart Building is the one that uses technology and processes to create space that is safer and more productive for its occupants and more operationally efficient for its owners. In such a building, network of electronic devises monitor and control the mechanical and lighting systems to reduce energy consumption and maintenance costs. Lighting is controlled with a system based on sensors, which can detect the presence of occupants and the relative darkness and modulate lights accordingly. Air handling units can mix outside air to regulate temperatures in various sections/rooms of the building. Sensors are placed in rooms and air-ducts to monitor temperatures. Such Buildings have hot water systems to supply heat to the building’s air handling units and chilled water systems to cool its air and equipment with sensors maintaining temperatures at optimum levels. They can also use Geothermal Energy for cooling or heating of Buildings. Intelligent buildings also have alarm system. While fire and smoke alarms are common, other types of alarms for reporting critical faults in the mechanical and electrical systems can also be effectively used. With such concepts, a quantum of energy can be saved and hence in the category of sustainable development.

A truly sustainable building construction should be energy efficient, incorporate concrete that contains the least amount of Portland cement and use of large amount of supplementary cementitious materials and recycled materials from waste materials. It should also optimize on the use of water & energy consumption and use non conventional energy & waste recyclable items.