Resources For Clean Environment And Green Construction Through City and River Waste Processing

Waste Generation:

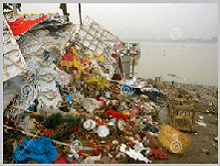

Huge amount of municipal solid waste is generated every day in each Indian city or town. It is estimated that per capita waste generation in major Indian cities generally range from 0.5 to 1.0 Kg per day per person, depending upon its location and time of observation. The central pollution Control Board estimates the current quantum of municipal solid waste generation in India to the tune of 60 million tons per annum. The waste contributes to greenhouse gas emissions and thus also adds to pollution or global warming. Some typical waste dumps on the river bank or on its nearby areas is shown in figure 1. Generally, because of above practices, the river water gets highly contaminated and unfit for drinking or even taking bath. Each of big and small cities, towns and village are responsible for discharging sewerage water and disposing garbage in it. Some of the main reasons of pollution and waste generation are given below:

1. At least 1500 drains or Nalas discharge directly about 6,000 million liters waste water in the river Ganga from about 180 towns and cities.

2. Generally, industrial pollutants are also discharged in this river, sometimes even without any primary treatment.

3. Some small builders or house owners, who are renovating their house or any building, also throw the demolition waste on the road sides as shown in figure 2 or on the banks of river, as there may not be any other free dumping yard nearby.

Holy River Ganga

People come to the banks of River Ganga to have a holy dip as shown in Figure-3. This river is considered to be most sacred river in the World. Many cities and towns are situated along the banks of this river. Following are some facts about Ganga.

1. Ganga Basin covers four countries: namely India, Nepal, China and Bangladesh.

2. Ganga Basin covers 100 million (10 crore) hectares of land in these four countries.

3. The Ganga basin is one of those basins in the world which still has water in it.

4. The river travels a distance of about 2,510 Km in India from Gomukh to Gangasagar through the states of Uttrakhand, UP, Bihar, Jharkhand and West Bengal.

5. Holy River Ganga is not alone in its existence; it is a group of rivers and tributaries which contribute water. Some of them are Yamuna, Bhagirathi, Akakhnanda, Mandakini, Dhouliganga, Pinder, Ramganga, Kali, Tons, Gomti, Ghaghra, Sone, Gandak, Kosi, Mahananda, Hindon, Chambal, Sindh, Betava etc. Thus several rivers join together with major tributary being river Yamuna, which meet river Ganga at Prayag.

6. Many big & small cities, towns and villages like Haridwar, Kanpur, Allahabad, Varanasi, Patna and Howrah etc are situated on the banks of river Ganga.

7. Ganga is a source of livelihood for more than 350 million people in these five states.

Municipal Solid Waste and Waste Material in the River

The pollutants and wastes in the river and on road sides are in the form of solid waste and liquid pollutants. In this article solid Wastes and pollutants are discussed. The main solid wastes in the river or on roads are in the category of

- Biodegradable matter like flowers, food items, grass etc.

- Non biodegradable items like polythene bags, plastic containers, metalcontainers, demolition waste, bones etc.

Some of such wastes are: Green wastes like flowers, farm waste, food waste, animal by-products etc. Non-biodegradable waste is that waste which cannot be degraded but some products are recoverable from it. These waste may be industrial and business waste, clinical waste, commercial waste, construction and demolition waste (C&D waste), some household and domestic waste, electronic waste (E-waste), grey water, hazardous waste etc.

City and River Waste Analysis:

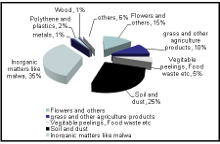

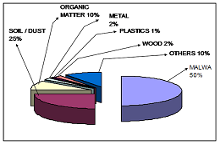

On analyzing a typical general waste collected from road sides and from the banks of River Ganga near the city, the waste product distribution has been found out. This at any one time may be as shown in figure- 5 and 6. This distribution may change from time to time and place to place. Generally some of the waste components in these are,

- Organic matter or vegetable, flowers, food items and other house hold items

Animals, Bones, Wood etc - Soil or dust

- Polythene or plastic waste, plastic containers and bottles etc.

- Construction and Demolition (C&D) waste or Malwa

- Metal containers or metal waste

- Typical product analysis of Waste recovered from river or from itsbank

- Typical analysis of Waste distribution from any Road Side Dump

Management of Waste:

Waste management is generally undertaken to process / reduce or dispose it off. Important goal is to identify advantages and disadvantages of different methods for treatment of solid waste, and to recognize critical factors in the systems, including the background systems, which may influence the outcome. Included in the system can be land filling, incineration, recycling, digestion and composting. The waste fractions considered are the combustible and recyclable or compostable fractions of municipal solid waste and river waste. A waste hierarchy suggesting the environmental preference of recycling over incineration or land filling is often put forward and used in waste management policy making. Its effect on environment and health of river and quality of water and thus human health & Environment is not affected. It also affects the aesthetics and amenities around city. The waste management is also carried out to recover useful material or resources from it. The management of waste requires various procedures in coordination to handle and process it, as it might contain some toxic compounds that may be harmful. Generally Mother Nature and river water recycles or consumes most types of waste. However, if we produce much more waste then the nature or river is capable of consuming or recycling, then it results in pollution of water, land and environment. Waste Management involves the following steps.

- Collection and transport

- Sorting

- Incineration

- Recycling – physical and biological processing

- Product making or resource supplement and

- Composting to get soil modifiers

- Energy generation or recovery (sometimes)

- Disposal of remainder

Recycling the Waste:

Step 1: Collection: Waste materials differ from river to river, time to time and place to place. The waste should be collected (if possible), biodegradable and recyclable separately. Participation of private organizations or of rag pickers in India may also be explored.

Step 2: Processing: Waste may be sent to a recovery industry / facility to be sorted and prepared into manufacturable commodities for manufacturing or processing for useful product or materials.

Step 3: Manufacturing Technologies: Once waste is separated and cleaned, the biodegradable & recyclables are ready to undergo the third phase of processing. Many products can be manufactured with total or partial recycled content. Some household items that contain recycled materials include composting for manure or producing energy etc. From remainder non-biodegradable waste we can convert or recover resource or make containers, packing cartons, granular for making polythene begs etc. It can also produce construction materials like aggregate, if demolition waste is also a part of it. Many technologies for recovering products have already been developed which are available. Some are given here.

Technologies for Recovery of Useful Material from Waste:

Technologies for treatment of various types of waste are quite different. Few technologies are given here. Out of all methods, processing or recycling is most relevant as it will also generate resources and thus conserve the natural wealth. Many of the materials which may be recovered are very useful and can replace resources to a great extent. This can simultaneously generate employment as well.

A) Processing of Non-Bio degradable Waste

i) Use of Demolition Waste in making Concrete material and Concrete Bricks:

The demolition waste from small city buildings being renovated or demolished is many times thrown on the road sides as shown in figure-2. This can be collected and foreign matter sorted out from it. This MALWA can be broken into the pieces of approximately 20 & 10 mm size with the help of light crusher. Then such pieces or matter can be mechanically sieved through IS sieve 26.5 mm, 12.5 mm and 4.75 mm to remove higher & finer particles. The higher size can be broken again into smaller size. Thus we can get aggregate of 20mm and 10mm nominal size. Finer particles separated out from 4.75 mm sieve can be used for plinth filling or for road embankment.

Using such aggregate; a concrete mix can be made using nominal amount of cement as per mix design, say 150 Kg per cum of concrete and other ingredients as shown in figure-8. This low grade concrete can be used to cast bricks/blocks of conventional size 9″x4½”x3″ or similar other items like interlocking blocks by hand molding or in block making M/c. After casting, these can be put in curing tank or spread on the ground. For curing such bricks on ground, the water is sprayed a few times in the day.

As seen from figure 9 and shape or tests, these bricks are similar to burnt clay bricks. The cost of such burnt clay brick is similar to conventional burnt clay bricks. The weight of such bricks is about 15% more but the strength is about 15 MPa which is almost one and half to two times conventional burnt clay bricks. Following are some of the advantages of using Recovered Aggregate concrete Bricks/Blocks.

As seen from figure 9 and shape or tests, these bricks are similar to burnt clay bricks. The cost of such burnt clay brick is similar to conventional burnt clay bricks. The weight of such bricks is about 15% more but the strength is about 15 MPa which is almost one and half to two times conventional burnt clay bricks. Following are some of the advantages of using Recovered Aggregate concrete Bricks/Blocks.

- By making bricks from such demolition waste aggregate, the manufacture of conventional clay bricks can be reduced.

- Simultaneously, the fertile top soil of earth, which is used otherwise in making burnt clay bricks, is saved for agriculture and thus less pressure on environment.

- By making such bricks out of C&D or demolition waste, road sides and river banks can be kept clean.

- It is also possible to use MALWA bricks in Roadside pathways and building foundation where they are found to be quite suitable. They can also be used in building construction instead of burnt clay bricks.

- Such aggregate can also be used in making low grade conventional Concrete for Structural elements and in foundation along with small utility items like benches etc.

- Finer material after crushing of demolition waste and passing through 4.75 mm IS sieve; can be used in embankment /plinth filling. It can also be taken back to river bed in the same truck which brings sand from there.

- Such processing of the waste will make the system sustainable and the Roads can be kept clean.

ii) Plastic Waste and its Recycling:

Normally people carry shopping, flowers and eatables etc in plastic beg. After its consumption they normally throw or leave plastic bags there itself. Otherwise also polythene bag are used as carry bags, packing material etc. Its use is increasing day by day. But, as polythene bag waste is a big nuisance, so many times its use is banned in the city or in that area but it is a very convenient method of carrying small items. In general, the consumption of polythene bags has increased from 4 million tons/annum in 2001 to about to 8 million tons/annum during the year 2010 and it is increasing every day. Nearly 50 to 60% of the total polythene bags are consumed for packing or as carry bags. Though polythene bags are non biodegradable item, however some of them can be used as byproduct for making granules for fresh bags or make plastic furniture, containers, flower pots etc. Another technique of its use has been investigated by author and it is described here.

Use of Polythene Waste in making Perforated Blocks:

Ground water level is going down continuously and it is urgently required to replenish the ground water by all possible means. Rain water harvesting through roof top is a common practice and its method of collection is well known. However, rain water harvesting from road sides, pathways, driveways and other plain areas in city is still not common. On the other hand cities are expanding and getting extensive construction for Hi-rise jungle, roads, industry etc giving rise to major climate change.

Thus plastic waste is also scattered everywhere and even in or around city roads, rivers etc. A typical waste dump and offerings in river or banks are shown in figures 1 & 4. Generally such waste dump from or around river or in cities has about 2% plastic waste in it. Even on the banks of river in holy cities such scenario can be seen everywhere.

Plastic-Waste coated aggregate as Perforated Polymer Concrete Blocks:

Polythene waste can be used for making such blocks called “Perforated Polymer Concrete” as investigated. Most plastic waste or polythene bags are in the form of Polymer and some of its properties are useful. The plastic waste can be shredded in small pieces as shown in figure 9. The aggregate of size 10-12 mm is heated to a temperature of around 130 – 1400 C. The shredded plastic-waste is poured over hot aggregate as shown in figure 9a, while constantly stirring /mixing to give a uniform distribution of plastic waste over aggregate The plastic waste gets softened easily without much evolution of gas at such temperature. Such plastic waste -aggregate composite after heating to a temperature of about 1300C and spreading over the mould and compacting can be used in casting perforated elements. The molten plastic waste inhibits good binding property as shown in figure 9b.

The hot plastic waste coated aggregate can be cast in the form of small thick slabs or blocks and compacted as seen in figure 10. The coated plastic material remains intact with aggregate and has sufficient voids to give perforations. Though binding strength of the plastic waste /polymer depends on the type of plastic waste, but generally it is good. The experiment shows that the blend has good resistance towards water and can be used where perforations are required. However, their tensile or bending strength is low.

Use of perforated Concrete in city roads, pathways etc:

Perforated concrete elements; either of cement concrete or of polymerized plastic waste concrete could channelize the rain water and replenish the water into ground water buffs or used for ground recharging. They can be gainfully used on the shoulders of city roads, pathways, driveways and for many other open spaces which will allow rain water to seep into ground. Some of the advantages are:

- Use of perforated concrete blocks is good for transforming rain water in the ground.

- It will recharge/replenish the ground water level.

- Disposal of Plastic Waste will become easier.

- It can generate work for unemployed people like in collecting appropriate plastic waste by Rag pickers etc, and deposit it at hot mix plants (which can be set up outside city).

- It will avoid disposal of plastic waste by incineration and/or land filling.

B) Use of Bio-degradable waste in making soil Improvers or Manure:

In Municipal Solid Waste (MSW) and near river Ganga or around, there are many elements like vegetable peelings, waste eatables, offered flowers etc which are biodegradable. Other similar wastes are food waste, agriculture waste, animal dug etc. In the city or on the banks of Holy River many temples are also located. In these temples tons of flowers are offered daily. These are also biodegradable and have to be disposed off. Thus, a large volume of organic material is available from MSW or animal shelters etc. This resource can be utilized by properly composting it into a value-added end product called Soil Improvers which is of superior quality manure to feed our hungry agriculture farms. These have many nutrient / organic matters for hungry soils. The bio-degradable waste can be converted to compost by NADEP technology or Vermi Method. In short these methods are given here:

i) NADEP technology:

Adopting”NADEP technology” it converts the bio-degradable waste to organic manure. In this method a rectangular box type brick structure of about 3m length x 1.6m width x 1m height is constructed on leveled ground. The brick-work is done using plain cement sand or lime mortar. The top layers are done with little richer mix so as to give strength to structure. It may be provided with perforations in the walls all around by leaving half brick holes while doing the brick work. The floor can be lined with plain bricks or simple earth.

Waste material required for filling such size of Box includes: About 1400-1500 kg biodegradable / agricultural waste or flowers; 100-150 kg animal dung; 800 kg field soil. It is mixed well with cow dung & animal urine; water 1000-1500 liter. When all material needed is ready, the filling of tank is completed within 48 hrs by pouring the material in layers. First is 15 to 20 cm with flower or organic waste keeping it wet with water or animal urine mixture, 2nd layer with 10 kg cow dung with about 150 liter water, 3rd layer with 50-60 kg mud mixed with water like a paste? Like this 4-5 layers are poured and finally the filled tank is covered and sealed with a uniform paste of moist mud. The box top is kept moist by spraying water from time to time for about 2 – 3 months in summer time.

Approximately 5-6 ton of good manure is ready per tank in about 3 months, containing nitrogen-0.5 %’ phosphorus-0.5-0.6 %, potash- 1.2-1.4% plus all the other nutrients required for agricultural crops which is good. Besides this, NADEP compost being rich in humus also improves the physical structure of farm soils.

ii) Vermi-composting:

Vermi-composting uses earthworms to turn biodegradable or organic wastes into very high quality compost. This is one of the best ways of composting many types of wastes including flowers, kitchen and animal waste etc. For this technology, the most convenient pit or chamber is of size is 3m x 1m x 0.75m as shown in figure 12. The size and number of chambers can be changed or determined according to the volume of flower or agricultural waste mixed with animal dug. Earthworms are introduced into the loamy material / soil, which they will inhabit as their home and grow. In vermi bed of about 50 to 60 cm thick, about 200 or 1 Kg earthworms are introduced in the pit. The bedding for vermin composting system must be able to retain both moisture and air while providing a place for the worms to live. About 1 ½ to 2 tons of good manure can be ready from such pit in about 2 months.

iii) Kitchen Waste Manuring:

Small plastic storage containers in convenient or variety of sizes as shown in figure 15 can also be used for Vermi-composting. These containers can easily be transported to suitable locations. These can be made or casted out of waste plastic begs converted to granular as discussed earlier. These containers and method can also be used by house hold Kitchen waste to convert into manure for kitchen garden.

Similar to NADAP technology this Vermi-Composting contains more nitrogen, many times more phosphorus and potassium. They are rich in humus acids and improve the structure of soil.

- Small Plastic containers for Vermi Composting

C) Generating Energy from Waste:

How to Produce Energy from Waste: Waste to energy is an emerging innovative set of technologies aimed at better protection of environment with minimum damage to ecosystem. This technology stands for Mechanical Biological Treatment (MBT). This technology uses domestic waste as well as industrial and commercial waste to generate energy/products. The energy generation from these technologies at present is at small scale. In this process generally Biodegradable waste or Waste Plastics is used.

The most common and popular method for waste to energy generation is ‘Incineration’ In simple terms it stands for waste treatment process, where the organic form of waste is collected and burnt at high temperatures. The heat generated from this thermal process is used to create energy. Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration and other high-temperature waste treatment systems are described as”thermal treatment”. Incineration of waste materials converts the waste into ash, flue gas, and heat. The ash is mostly formed by the some constituents of the waste, and may take the form of solid lumps sometimes or particulates carried by the flue gas. The flue gases must be cleaned of harmful gaseous and particulate pollutants before they are dispersed into atmosphere. The heat generated by incineration is used to generate electric power.

Incineration with energy recovery is one of several waste-to-energy technologies such as gasification, pyrolysis and anaerobic digestion. Incinerators reduce the volume of solid mass of the original waste by 80-85%. In many countries, simpler waste compaction is a common practice for compaction at landfills. Denmark and Sweden have been leaders in using the energy generated from incineration for more than decade. It uses in localized combined heat and power facilities supporting district heating schemes. Waste incineration produces about 4.8% of the electricity consumption and 13.7% of the total domestic heat consumption in Denmark.

Conclusions

The MSW are to be dumped somewhere which needs lots of free space or waste ground and corresponding transportation. If technologies presented here are utilized to process the solid pollutants to get some useful products then so much waste land will not be needed. Technologies and processes given here with corresponding method are useful as suggested. For such waste processing small units in outskirts of city or nearby areas or on the spot itself may be established for minimizing transportation cost.

Waste processing will not only clean but will also generate the availability of resources and employment. This will also give good environment and minimize Green House Gases.

References:

1. Gupta Y. P. Book on”Concrete Technology and Good Construction Practices”, New Age International Publishers (P) Ltd, Publishers, New Delhi, 2013.

2. Gupta Y. P.,”Use of Recycled Aggregate in Construction: a Need for Sustainable Use of Resources for Better Environment”, 8th International Conference on Concrete in Low Carbon Era, Dundee, UK, July 2012.

3. Gupta Y. P.”Use of MALWA Recycled Aggregate in Concrete Construction: a Need of Society for Better Environment”, Journal of Indian Concrete Institute, Vol. 10, No. 4, Jan 2010.

4. Gupta Y. P., S. Tiwari & J. K. Pandey,”Utilization of Plastic Waste in Construction of Bituminous Roads”, National Seminar on Environment Protection Through Organic Farming & Waste Management, YASTK & IE(I), Allahabad, February 2009.

5. Gupta Y. P.”Use of Recycled Aggregate in Concrete Construction: a Need for Sustainable Environment”, 34th World Conference in Concrete and Structures, Singapore, August 2009.

6. Themelis, Nickolas J. An overview of the global waste-to-energy industry, Waste Management World 2003.