Plan the Future Townships through Renewable and Waste Material and Technology

By

Dr. Y. P. Gupta, Chairman

Yash Krishi, Taknique Evam Vigyan Kendra, Allahabad

Ex Technical Advisor, Naini Bridge, Professor(Retd.), MNNIT, Allahabad

Mail id [email protected]

If equipment or process fails to function, it does not hurt anyone. But if a building collapses, it hurts or kills people, affects public safety, and dents the credibility of planners, designers, engineers, and a host of many other professionals associated with the buildings/city design. Great responsibility rests on the shoulders of Planners & Engineers as human civilization is increasingly getting urbanized.

- They would need to plan future cities that would be safe, healthy, and especially sustainable in view of environmental changes, migration of people, shortage of resources, and waste generation.

- Thus Planners and engineers must explore the possibilities of having such megacities, rural cities, floating cities, frozen cities and cities on other planets. As more and more people move into cities during the current century, there is a possibility of people living in skyscrapers and having leaders connecting the high rise, thereby eliminating the necessity to come down.

- With oceans rising in the wake of climate change, several coastal cities would go underwater, and planners may also have to think of “floating cities.” One such project has been conceived with regard to Miami, Florida. Also, one such hotel/restaurant has come up in UAE which is inside Sea.

- The planers may also have to re-conceive the roads/pavement for future cities as they may become an interactive space for future citizens and will increasingly be used to tap solar and wind energy or for installing charging stations as mobility solutions are switching over to electric vehicles.

- This may lead to choking of corridors in the air, prompting further research into mobility. According to environmental needs, new construction material and composite material will have to be found as resources are diminishing concrete is not green and steel will become a material of the past.

- Seattle in USA and Japan already have glass bridges while bamboo could also be tried in the future. It is also necessary to try waste generated & its utilization and of nano-material. The researchers are processing to find newer material and reuse waste for future buildings.

- The need is for finding new material as sustainability has acquired central status in the present context of climate change. These days Delhi is getting ready by making Monumental Structures with waste material and exhibiting as Bharat Darshan

II. Use of Waste as Upcoming Construction Material:

a. Waste Definition:

Waste is unwanted or undesirable material left over or thrown after the completion of a process. In other words, it can also be stated that any substance or matter which the holder discards or intends to discard is waste or which, as such cannot be used again.

- Waste is generated from all directions. It may be from Industry, Municipality, Hospitals, Electronics, and Agriculture or from any other process of human or animal use.

- The waste may be in the form of solid, liquid, or in gases. Not only do they require huge space to stock it but also pollute the environment. The polluted environment is harmful to human health and for the sustainability of the system.

- Thus, the generation of waste must be minimized or recycled for human use. Innovative research and new developments are needed which will directly deal with the resource crunch and process waste for the replacement of resources on the 3R principle.

b. Waste Analysis:

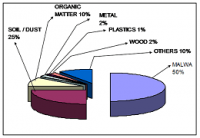

On analyzing a typical waste dump collected from roadsides in the city, the waste product distribution can be found out as shown in Figure 2. Generally, some of the waste components in these are:

- Organic matter or vegetables, flowers, food items, and other household items

- Animals, Bones, Wood, etc

- Polythene or plastic waste, plastic containers, bottles, etc.

- Construction and Demolition (C&D) waste or MALWA

- Metal containers or metal waste

- Electronic items etc. This distribution may change from time to time and place to place.

III. Various type of Large amount of Waste Material possible for Construction Industry:

Many types of waste can be used in Agriculture/Horticulture and Construction industry or in some human needs after its processing. Three major amounts of wastes are from municipality, industry, Electronics, and building demolition. Wastes like demolition waste, fly ash – an industrial waste, can be easily used in Construction Industry.

A summary given here is only about a few wastes that can be used in the construction industry for infrastructure. However, properties – all physical, chemical & biological must be investigated to see the suitability and compatibility as one component of construction materials.

Few types of waste materials which may possibly be used in Construction industry after processing are given below:

Demolition Waste or C & D Waste or Recycled Concrete Material

Fly Ash

Microsilica or Silica Fume

Ground Granulated and Air-Cooled Blast Furnace Slag

Red Mud

Waste Plastic

Old Tires / Crumb Rubber etc

Used Metal & Steel Reinforcement

Agriculture waste, Rice Husk Ash and other wastes

IV. Processing of Non Bio-degradable Waste and its Use in Construction:

Details and processes of some of the waste materials for the construction industry are given here.

A) Demolition Waste or Construction And Demolition Waste (MALWA):

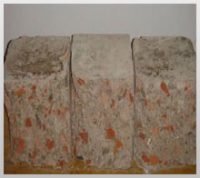

The construction industry during rehabilitation, repairs, and modernizing the buildings/bridges, etc produces huge waste called C & D waste or demolition waste or MALWA. The Dumping of such waste occupies huge space on the roadside as shown in Figure 3 and contributes to not only environmental pollution but also traffic hazards. Such waste should be reduced by its recycling.

Manufacturing Bricks / Blocks With Concrete using Such Recycled Aggregate:

Such C & D waste can be used as one component of concrete. A typical application of such concrete is in the casting of the conventional type of bricks like burnt clay bricks. A simple Concrete mix says M15 can be designed with waste recycled aggregate with different cement contents and fly ash. With such concrete mix – bricks can be cast. Materials can be mixed in a typical weigh batcher.

Typical bricks of size 230x115x70 mm are shown in figure 4. They can also be made of any other shape and size. They can be cured in the open with water sprayed a few times in the day. These bricks can be used similar to convention burnt clay bricks.

Performance and use:

It has been seen that both its compressive strength and density are higher or similar to conventional clay bricks. Many times they are superior to brunt clay bricks as their average compressive strength is about 15 MPa or more. The weight or average density is about 2.25 g/cc.

They can be easily used in the conventional type wall construction of buildings as shown in figure 5 or on the roadside pavement etc. Such bricks generally perform better than conventional burnt clay bricks. The crushed form of such recycled aggregate bricks is investigated and is shown in figure 6. These Crushed forms of Recycled Aggregate bricks are showing the brick pieces in them.

B) Fly Ash:

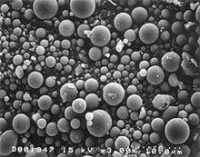

Fly ash and Bottom ash are the by-products produced during the operation of coal-fired Thermal power plants. Fly ash particles are coming through Chimneys and are very smooth and quite spherical in shape. These particles range from 1 to 150 µm in diameter, depending on the type of collection system. A typical shape of fly ash particles is seen in figure 7.

Use of Fly Ash as supplementary cementitious materials (SCM):

Fly ash particles finer than 10 microns get adsorbed on cement particles giving a negative charge causing dispersion of cement particles, thereby releasing the water trapped within the cement particle flocks and improving workability. Fly ash particles are the glassy and amorphous phase of them and diameter less than 45 microns have good pozzolanic reactivity.

Particles more than 45 microns in size are less reactive and therefore likely to increase the water requirement. Particles, smaller than 10 microns, are the main contributors towards the 7 to 28 days strength. Sizes between 10 to 45 microns react slowly to give the full strength in 28 days to a longer duration. Some of its specific uses are:

- Mix fly ash with clinker to make blended or Portland Pozzolana Cement

- It can be used as a partial replacement of cement in concrete. Generally, carbon content, measured by the loss on ignition (LOI), should be less than 4%. In such a Mix, fly ash is taken as one component in making concrete in addition to cement, sand, and aggregate.

- Dry fly ash can be used as an inert fill material for Road/soil embankments.

- It can also be used as supplementary cementitious material to improve the stability of bituminous concrete.

C) Microsilica or Silica Fume:

Microsilica (SiO2) also known as Silica fume, is a byproduct of the reduction of high-purity quartz with coal in electric furnaces in the production of silicon and ferrosilicon alloys. Silica Fume is also collected as a byproduct in the production of other silicon alloys such as ferrochromium, ferromanganese, ferromagnesium, and calcium silicon.

- Earlier such Silica Fume used to be discharged into the atmosphere but later because of environmental concerns it necessitated the collection and its use in various applications. A typical form of Microsilica in powder form is shown in figure 8.

- This product has extreme fineness as shown in figure 8 and because of high silica content, Silica Fume is a highly effective pozzolanic material (ACI Comm. 226 1987b) and with its use, the concrete can achieve very dense concrete and much higher strength like 150MPa or more.

- Silica Fume is available in two forms: dry and wet. Dry silica can be provided as produced or in dense form with or without dry admixtures. Silica Fume slurry with low or high dosages of chemical admixtures is also available.

D) Blast Furnace Slag (BFS):

Blast furnace slag is a byproduct from the manufacture of pig iron and is obtained through rapid cooling by water or quenching molten slag. Iron ore, as well as scrap iron, is reduced to a molten state by burning coke fuel with fluxing agents of limestone and/or dolomite. Blast furnace slag is a nonmetallic by-product produced in the process of steel production.

In this process of reducing iron ore to iron, a molten slag forms as a nonmetallic liquid (consisting primarily of silicates and aluminosilicates of calcium and other bases) that floats on top of molten iron. The molten slag is then separated from liquid metal and cooled. Different forms of slag product are obtained depending on the method used to cool the molten slag and subsequent processing. The aggregate form of such slag is shown in figure 9.

Air-Cooled Blast Furnace Slag (ACBFS), (one of the various slag products) – is also available when the liquid slag is allowed to cool under atmospheric conditions. India produces more than 10 million tonnes of Blast Furnace Slag every year and it is increasing with the increase in steel production.

Possible Use & Some Properties: Crushed ACBFS can be used in nearly all mix applications utilizing it as natural aggregates, such as bituminous and portland cement concrete, embankment, or sub-base and fills. ACBFS has potentially favorable resistance to polishing, weathering, durability, and abrasion.

E) Ground Granulated Blast Furnace Slag (GGBFS):

It is a pulverized/ground Blast Furnace Slag that is reduced to a small particle size similar to cement fineness. Thus it is a fine powder and behaves as cement-like material.

GGBFS is a non-crystalline material varying in size depending on its chemical composition and method of its production or of its iron source. If slag is properly processed then it develops hydraulic property and it can be effectively used as pozzolanic material (powder form) in cement clinker similar to fly ash as shown in figure 10. Thus its properties and use are similar to cement and can act as a cementitious material. It is a glassy granular material that allows its use as partial cement replacement.

F) Red Mud – used for Making Bricks:

Red mud is the by-product of the manufacture of alumina from bauxite by the Bayer process is shown in figure 11. Every ton of alumina produced leaves about 1 ton of solid residue in suspension and 4 tons of slurry. The utilization of red mud is of great significance from the point of view of resource conservation & sustainability of the aluminum industry. There is an effective way of utilizing alumina red mud to make bricks. Using red mud for the production of bricks is a simple and economical method to utilize this waste material.

- There are two basic processes. The first requires that the red mud be pressed into blocks and fired at high temperatures. The second process mixes the red mud with binders. The mix makes use of either hydraulic cement for hardening or firing at low temperatures.

- The addition of red mud to concrete leads to modification of the properties. The addition of red mud, replacing about 30% of sand exhibits higher strengths than concrete with quartz aggregates for built-in piles and has better durability than standard concrete in defined conditions.

- The addition of slag to red mud and firing improves the crushing strengths of the aggregates and decreases the sintering temperature.

G) Plastic Or Polythene Waste from Houses and Industry:

A typical garbage dump on the roadside with plastic bags is shown in figure 1. The ingredients distribution analysis of such garbage dump shows about 1 to 2% Plastic waste in such garbage dump as shown in figure 2.

After sorting out from waste dump a typical plastic bags after cleaning is shown in figure 12a. Such Polythene pieces are non-Bio-degradable, so they cannot be decomposed and used as organic manure. Some plastic bags can be reused or they can be reprocessed by converting it to granular form and then re-rolling it in the form of sheets. The rest of plastic waste is either land-filled or incinerated. Both processes are not eco-friendly and they pollute the land and water bodies.

Possible Use: Such Plastic or single-use plastic is considered a pollution menace, but it can be used in the construction Industry/processes to some extent. Plastic waste or polythene begs is a form of Polymer and its properties are similar to the polymer to some extent.

The utilization of Plastic Waste was tried by the author in two applications in the highway construction industry. These are given in brief here. The studies on the thermal behavior and binding property of the molten plastic waste were also carried out on the preparation and use of plastic waste-bitumen blends.

i) Use of Plastic Blend Bitumen in Bearing Coat of Road Pavement:

The plastic blend bitumen can be prepared by heating the normal Bitumen of grade 80-100 up to 150-1600C. Simultaneously shredded waste plastic in smaller pieces is added in hot bitumen and stirred well till it melted fully in bitumen as shown in figure 13. First, the properties of such Plastic waste – Bitumen blend are found called polymerized Bitumen. These properties are similar or even better than the original bitumen. This blend can be used for the top layer of the road surface as is common for SDBC or Bituminous Concrete.

ii) Use of Plastic-Waste as Perforated Polymer Concrete Blocks:

Plastic blended bituminous material can be used with 5 to 10 mm size aggregate and stone dust mixture similar to normal SDBC Mix. Bitumen mix can be developed which is the right Job mix formula. It may be blended with about 1 to 1.5 % waste polythene for such mix. The plastic waste mixture can be used for producing Perforated Polymer Concrete.

The aggregate is heated to a temperature of around 1400 C. The shredded plastic waste is added over hot aggregate while carrying on constant stirring to give a uniform coating of plastic waste over aggregate as shown in figure 14. The hot plastic waste-coated aggregate can be cast in the form of block/slab and compacted, as seen in figure 15.

V. Use of Bio-degradable Waste for Producing Soil Improvers or Manure:

In Municipal Solid Waste (MSW) and near river Ganga or temples or around, there are many items like offered flowers, vegetable peelings, waste eatables, agricultural waste, etc which are biodegradable. Thus, a large volume of organic material is available from MSW or from temples, agriculture rivers, etc. This resource can be utilized by properly composting it into a value-added end product called Soil Improvers for our hungry agriculture farms. These have many nutrient / organic matters. The bio-degradable waste can be converted to compost by several methods as given below:

a) NADEP technology:

Adopting “NADEP technology” converts the bio-degradable waste to organic manure. In this method, a rectangular box-type brick structure of about 3m length x 1.6m width x 1m height is constructed on the ground. A typical NADEP Box is shown in figure 16.

Waste material required for filling such size of Box includes all biodegradable waste and water. After this, some decomposing material can be added The box top is kept moist by spraying water from time to time. Approximately 5-6 tons of manure can be ready per NADEP, containing nitrogen, phosphorus, potash plus all the other nutrients. Besides this compost is rich in humus also improves the physical structure of soils.

b) Vermi-composting Technology:

Vermicomposting uses earthworms to turn biodegradable wastes into high-quality compost. This is one of the best ways of composting many types of waste. For this technology, the most convenient pit is of size 3m x 1m x 0.75m or similar as shown in figure 17.

The Bio-degradable waste is cut into pieces and then they are filled in such pits. After this, some decomposing material is added Earthworms are introduced into the Bio-degradable material, which they will inhabit as their home and grow. The size and number of chambers can be made as desired. Good manure can be ready from such pit in about 2 months’ time.

VI. Generating Energy from Waste:

- For this process, generally Biodegradable waste or Waste Plastics are used. The most common method of converting waste to energy generation is ‘Incineration‘.

- In simple terms, it stands for a few types of waste treatment processes, where the Biodegradable form of waste is collected and burnt at high temperatures.

Waste processing that is conducted involving high temperatures is called Thermal treatment. The heat generated from this thermal temperature is then used to create energy and used to generate steam or similar to run turbines. Several countries in the world, especially in Europe are experimenting with Incineration as an alternate means of energy production. Following Technologies as generally used.

Thermal technologies

Non-thermal technologies

Fermentation is also being developed as a form of waste to energy management. The process works as a boon for developing countries for creating low energies also for cooking and lighting in homes. Both China and India are extensively using this technology.

VII. Recommendations:

Waste processing will not only clean but will also generate the availability of resources and employment. This will also give a good environment and minimize Green House Gases. Following steps may be taken to process the waste & use it in construction.

1.Every house and street should be provided three or more containers to collect different types of waste as for:

Kitchen waste, Flowers etc – Bio degradable waste

Plastic or polyphone type of waste like bags, milk packets, etc

Other nonbiodegradable waste like bottles, tins, metals, electronics, etc.

2. All these wastes should be collected separately hopefully by different teams and unloaded in the corresponding industries which must be established to process them. The industries should be on the outskirts of the city – may be in all four different directions of town for the convince of transportation and processing.

3. Another industry may be established for processing “Construction and demolition waste”. This industry should process the C & D waste or MALWA and make or caste bricks or blocks similar to burnt clay. Householders or Builders should dump the C&D waste in the processing Industry. Otherwise, the builder or owner must pay for transportation for collecting the waste. Then Builder can take back these bricks and use them in construction

4. Other wastes like Hospital waste, electronic waste, Hazardous waste, etc be collected separately and handed over to the corresponding industry

VIII. Ethical commitment fur Future cities and Conclusions:

- It is desired that ethics should come first among all the priorities of Planners and Civil engineers who are principally responsible for city infrastructure and City & building design where environment, health, and safety cannot be compromised.

- It is also indicated that asset management has also to be given priority in business across the globe. For the Planning of cities, the use of waste as renewable material will be advantageous from many angles. The technologies and the materials used for development should complement the use of local resources and proper waste management for the future living of people. A few advantages and methods of using waste in city planning are:

By processing C & D waste – one can make Concrete bricks or things like ferrocement wall panels, benches, etc. Thus disposal of Demolition Waste becomes easier.

By making use of locally available demolition waste aggregates, there would be a sufficient reduction in aggregate requirement at the construction site.

It is possible to produce a plastic waste modified Bitumen using this Bitumen for highways.

It can generate work for unemployed people like collecting waste by Ragpickers etc and deposit it at Bitumen or Hot mix plants or Concrete batching plants.

The Bio-degradable waste can also be used to make bio fertilizers and generate electricity. Technology for this has been developed.

The processing waste will also make the system Sustainable and can also conserve energy.

This will replace resources and thus use in future planning of cities and the construction industry.

IX. Cost involved in processing of Waste and making By-products:

A proper process has to be developed to find the quantity and quality of waste for cost determination. Following steps may be carried out.

Amount and quality of all categories of waste.

Cost of collecting the waste from house hold or from city streets.

Cost of establishing the corresponding industry in out skirts of city

Establishing the process of converting waste into resources as indicated above.

Value or cost of bi-products produced by this industry.

Methodology to sell, use or dispose of such bi-products in the market.

References:

1. Gupta Y. P. “Concrete Technology and Good Construction Practices”, New Age International Publishers (P) Ltd, Publishers, New Delhi, 2013.

2. Gupta Y. P., “Use of Recycled Aggregate in Construction: a Need for Sustainable Use of Resources for Better Environment”, 8th International Conference on Concrete in Low Carbon Era, Dundee, UK, July 2012.

3. Gupta Y. P. “Use of Recycled Aggregate in Concrete Construction: a Need for Sustainable Environment”, 34th World Conference in Concrete and Structures, Singapore, August 2009

4. Gupta Y. P. “Use of MALWA Recycled Aggregate in Concrete Construction: a Need of Society for Better Environment”, Journal of Indian Concrete Institute, Vol. 10, No. 4, Jan 2010.

5. Gupta Y. P., S. Tiwari & J. K. Pandey, “Utilization of Plastic Waste in Construction of Bituminous Roads”, National Seminar on Environment Protection Through Organic Farming & Waste Management, YASTK & IE(I), Allahabad, February 2009.

I. Introduction: